These ASRS reports show many ways to get something simple wrong. You’ll see how creative errors can sneak in and deprive us of the fuel that keeps us airborne.

Flight Planning

A pilot encountered 32-35 knot headwinds at cruise. At 2.5 hours airborne, the pilot decided to land for fuel because only eight gallons remained. Fifteen minutes later, the engine failed. He landed safely on a county road and found the tanks were dry.

After a review, the airplane’s fuel capacity was less than the expected 40 at 35-37 gallons, and the fuel gauge was too optimistic. The PIC wrote, “Flight planning will be better done and executed to prevent such an incident from happening again.”

An instructor and student planned a trip in three legs. The first leg burned 21 gallons, leaving 29 gallons plus a 10-gallon reserve to reach their second stop, where they would refuel. About 50 NM out, the engine began to run rough from a dry tank. They changed tanks to use some of their reserve. The engine failed as they turned base leg. They, too, landed on a highway.

The aircraft checked out, but they learned the fuel capacity was 48.2, not 50 usable gallons. Sound familiar? They encountered an unexpected headwind on the second leg and recalculated their fuel needs. Later they found a simple math error. Arithmetic skills sometimes atrophy in the cockpit. If you run numbers while airborne, be doubly sure of your arithmetic.

Alternators

Bad alternators can cause fuel starvation because electricity runs many fuel pumps.

A multi-engine pilot transferred fuel after two hours in flight but was unaware there was insufficient power to run the pump. An hour later, the entire electrical system failed, leaving him unable to transfer fuel from the auxiliary tanks into the empty mains. The low voltage also weakened all the avionics.

On final approach, the tower told him to go around. The pilot replied, “unable,” and landed. Good thing, too, because the engines failed as he pulled up to a maintenance ramp. The mechanic found a failed alternator and a depleted battery.

It might be challenging to detect a weakened electrical system from the cockpit, stressing that it is important to monitor all the gauges.

Fueling

On an IFR cross-country flight, the pilot of a Piper Apache saw oil coming out of the right engine. He shut it down and informed ATC that he needed to divert and receive priority handling. He landed safely.

Upon examination by a mechanic, one of the nuts on a recently installed vacuum pump was loose. The mechanic who installed the pump didn’t tighten it sufficiently. After repair the pilot departed IFR to his destination.

In “the duress of the moment,” the pilot thought he had enough fuel to get there plus a 90-minute reserve. However, he neglected to include the climb fuel to 12,000 feet. Over an airport, both engines began to run rough despite turning on the fuel pumps and switching tanks. He again requested priority handling and landed at the airport below.

Upon inspection, 16 gallons remained in all four tanks. Said he, “In the stress and haste of the moment, my mistake was not refueling before I left.”

A recurring theme in fueling mishaps is a distraction that disrupts the orderly flow of events. Try to manage interruptions and keep perspective.

A multi-engine instructor was giving dual to a commercial, multi-engine pilot on a cross-country flight. After landing, they went into town while the FBO topped all four tanks. During preflight, the instructor checked the left side for fuel; the trainee checked the right. They agreed that all four tanks were full. The fuel receipt read 26 gallons which was about right.

About halfway back to their home airport, the right engine failed. They diverted to a third airport.

The right main tank was empty. The 26 gallons went into the auxiliary and left main tanks. The right tank had ten gallons which got them halfway home. Had the trainee properly checked the right tank, he would have caught that the FBO failed to fill it. Perhaps he saw what he expected to see.

The instructor spelled out corrective actions. First, the PIC should always supervise fueling to prevent confusion and errors. Second, the PIC should always visually check the fuel tanks and never trust even another experienced pilot. Third, a gauge that reads significantly different from the visual check calls for a recheck.

He emphasized the need to stay proficient on engine failure procedures and have a VMC alternate. The result was an uneventful approach and landing.

Jet-A Blues

The need to supervise fuelers is evident from this pilot’s experience. After arriving at an airport, he requested 50 gallons of avgas—25 per side. On his initial departure climb, the cylinder head temperature on both engines spiked to the red line. He verified the mixtures were full rich, with airspeed and deck angle adjusted for better cooling.

He made an immediate 180-degree turn and landed. Afterward, he spoke with the lineman about fueling. He confirmed the aircraft had been misfueled with Jet-A.

One thing missing here is how one can mistake Jet-A for avgas during preflight. They smell, look, and feel different.

Distractions Aplenty

A twin Bonanza pilot ordered fuel, instructing the fuelers to top off both inboard tanks and add 20 gallons per side in the auxiliary tanks. He showed the line person each filler location and confirmed the fuel type as 100LL. He paid for the fuel but received no receipt due to a change in the FBO’s payment system.

The next day, using a calibrated dipstick, he discovered the left auxiliary tank was full. Before he could check the right side, his young child needed to use the restroom. Afterward, he noted the fuel quantity in each tank and sumped each.

He then did a weight and balance and found that he needed to reduce the weight to within maximum gross weight. The pilot removed some items and got it down. He flew uneventfully to a stopover airport but bought no fuel and didn’t dip the tanks.

The pilot departed for a third airport. About 25 minutes into the flight, the right engine lost power. Observing no fuel pressure, he turned on the boost pump. Fuel pressure and the engine returned to normal. He figured the engine-driven pump could have failed, but soon after the engine began surging again. Switching to the right AUX tank didn’t help. Having completed the checklist, he shut the engine down. Center suggested a diversion airport, where he landed safely.

Postflight, he found the right main tank dry. He thought he restarted his preflight in the wrong place and never checked the tank.

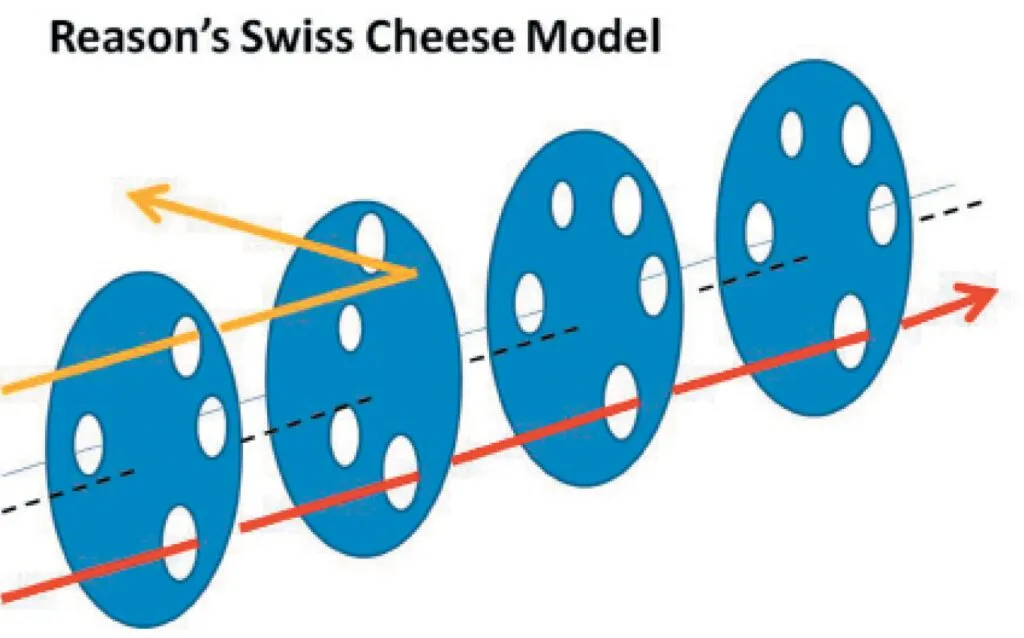

Like the Swiss cheese risk model, six holes fell into line. First and second, the lineman filled the tanks, but the pilot did not check the tanks as usual. Third, the missing receipt would have shown the wrong quantity. Fourth and fifth are the double distractions during preflight and having to remove items to get within weight. Sixth, buying fuel at his first stop would have revealed the dry tank, or seventh, failing to check the tanks there per his usual procedure before departure even though he added no fuel.

By his count, this conscientious pilot deviated three times from his usual habits.

Takeaways: Inspect fuel immediately after fueling. Don’t restart a preflight in the middle; begin it again. Dip all fuel fillers before every takeoff.

Leaks

Approaching his destination, the multi-engine pilot switched tanks from the AUX to the main tanks. About 20 minutes later, the left engine started to surge. All engine monitoring instruments showed normal values. The engine returned to standard cruise profile for about 15 to 20 seconds, then surged violently. Since the aircraft was flying erratically, he decided to cage the engine. Thinking of fuel contamination, he switched the left engine back to the AUX tank. The left engine continued to surge, then stopped.

Contacting Approach, he requested vectors to the nearest airport, which was his destination. A subsequent inspection by an AMT found a leak around the filler cap on the left main tank, which allowed the low pressure air over the wing to suction all the fuel out of the tank. The engine’s main filler cap is out of the pilot’s view. The power levers obstruct the fuel gauges, so his initial scan missed the empty left tank.

Critically, the pilot decided to troubleshoot the problem first because the engine ran smoothly for 3½ hours. This weighed heavily in the pilot’s decision to troubleshoot first. Had he scanned the left tank gauge, he would have known to shut the engine down immediately.

Many multi-engine pilots prefer basic troubleshooting before shutting an engine down unless the problem is obvious, like leaking oil or an empty tank.

Gauges

In the regulations, §23.2430(a)(4) says that each fuel system must provide the flight crew with a means to determine the total useable fuel available and provide uninterrupted supply of that fuel when the system is correctly operated, accounting for fuel fluctuations. Further, § 91.205 requires a “fuel gauge indicating the quantity of fuel in each tank.”

Fuel gauges are notoriously unreliable in older aircraft. Modern aircraft with electronic gauges or totalizers are much more accurate. The scenarios below illustrate the best and worst of older gauges.

Fifteen miles from his destination, the engine failed. Switching pumps and tanks failed. The pilot landed on a highway.

The cause of this fuel exhaustion accident was engine blowby. Blowby results when the compressed fuel-air mixture gets past the piston rings into the crankcase ventilation, usually due to worn piston rings or cylinders. The result was abnormally high fuel consumption at 11.1 gph. The pilot wished he had stopped for fuel before the tanks got “low to empty.” His words speak of poor judgment, but the gauges were correct.

The fuel gauges in this Cherokee Six were reputedly accurate within a gallon. It held 47 gallons for a 12-gallon flight.

The departure was on the right main tank, holding 11 gallons. At 500 feet in a climbing left turn, the engine failed. An instructor in the right seat set the fuel selector to the right tip tank containing 17 gallons, restoring power.

The right tank was empty, but the supposedly accurate gauge indicated 11 gallons. The pilot said he would believe the observed fuel level over the fuel gauges in the future. Ya think?

Minimum Fuel

The Cessna 320 entered the traffic pattern with 40 minutes of fuel. His first approach failed because he was sandwiched between two military jets. The tower told him to go around.

Entering the downwind again, the Cessna was at minimum fuel, and the pilot advised the tower, who promised to get him down.

The jet he followed took too long to clear the runway, and the tower issued another go-around. The Cessna pilot called “unable” and landed, but the runway was clear when he landed.

The tower and the Cessna apologized to each other. The pilot was uncomfortable doing another lap in the pattern. He decided to land “rather than risk a worse situation.”

An Extra 300 pilot entered the nontower traffic pattern to land behind a Cherokee and a Cessna 182, flying very wide downwinds. The Extra was forced to fly two 360-degree circles to increase spacing. Behind the Cessna, he flew S-turns on final but was forced to go around anyway. Then the Cessna announced it was disabled on the runway. Lacking the fuel to divert, he declared a fuel emergency on the CTAF and landed on the parallel taxiway.

The Extra pilot stated that flight schools don’t comply with airport rules that require tighter patterns and said the FAA should push schools to fly proper patterns.

In several ASRS reports, pilots refused to go around. They landed on runways, taxiways, and even in the grass adjacent to an unusable runway. Do what you must to prevent an accident, and don’t let anyone else, even ATC, fly your airplane.

Assert your PIC authority as needed to do the safest thing. Practice lost engine procedures and have an alternate airport ready. Fuel is one place where paranoia is a good thing.

Fred Simonds, CFII, has had two fuel leaks—one on the ground and one airborne.