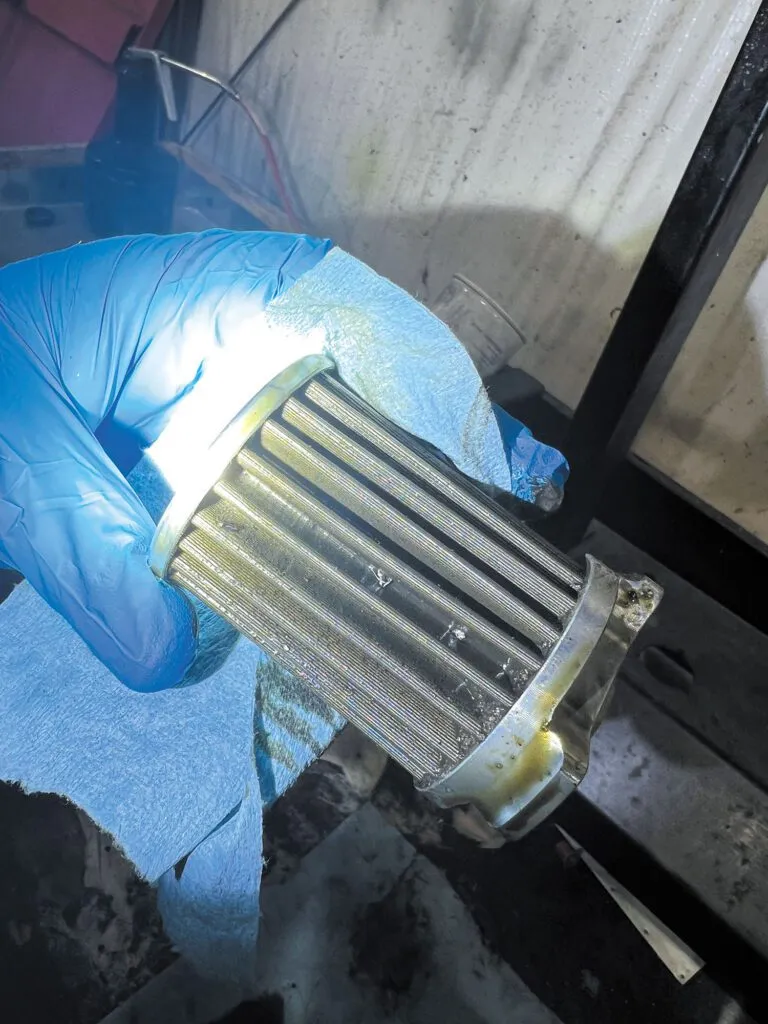

After over 20 years of ownership, it might be time for new engines in our Cessna 340. One engine is making metal, but we don’t know if it’s from inside the engine or from an accessory.

The engines have identical SMOH time and are past TBO. They both run fine. Before my time with the airplane, these engines both had a prop-strike inspection, meaning new bearings and such on the bottom end about 1000 hours ago. I put on new cylinders about 600 hours ago. So, my feel-good conclusion is that while overall the engine is past TBO, the attention it has received should make that okay.

There’s an interesting decision tree to all of this. My first choice is between just biting the bullet now and replacing the engines, or do some diagnosis to see if indeed the engine is worn out or if something external like an oil pump is making the metal.

There’s an interesting decision tree to all of this. My first choice is between just biting the bullet now and replacing the engines, or do some diagnosis to see if indeed the engine is worn out or if something external like an oil pump is making the metal.

I’m on my shop’s schedule to do the diagnosis. From there, the decisions branch. If the metal is coming from an accessory, do I simply overhaul that, or admit I’m putting a Band-Aid on a wound that could be considered a harbinger of more bad news?

Of course, if the metal is coming from inside the engine itself (likely a cylinder, cam, or lifter), it’s game over for that engine.

The next decision point arises if the engine is toast: Do I replace just that one engine or both? To me, both engines with the same times has a comforting symmetry. I’ve asked others and the market doesn’t seem to care about that. But, again, to me it suggests that possible improper maintenance, an unreported mishap, or other value-reducing happenstance required replacing an engine prematurely.

Having articulated that, I guess I have my answer. If one engine is toast, the other with the same times might not be far behind, so replace ’em both.

The breathtaking news in all this is that replacing both engines will cost more than we originally paid for the entire airplane. A long time ago, early on my aircraft-ownership adventure, a wise person once told me: If you can’t simply write a check for unexpected engine replacement you probably can’t afford the airplane.

Well, I can’t just write that check without first raising the funds. Nonetheless, that’ll set back the ol’ finances, but, it is an airplane, so…

But, this tale of woe doesn’t end there. Should I need new engines, the lead time for overhauls is six months. Diagnosing the metal as coming from inside the engine will leave it disassembled. It wouldn’t make sense to reassemble a worn-out engine—and I doubt my mechanic would sign it off anyway—so I’d be grounded for six months to get the engines, then another month or more to install them.

My path is first to diagnose. If the problem is external, I’ll repair that and preemptively plan and order overhauled engines for 2025. Of course, if the engine is doomed, I’ll be breaking in two new ones by late summer.

I wanted to share my analysis in case it resonates for you. Perhaps you would act differently, but I’m comfortable with my difficult choices.